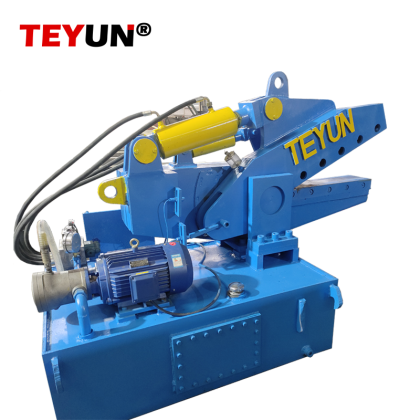

Hot selling vertical metal baler

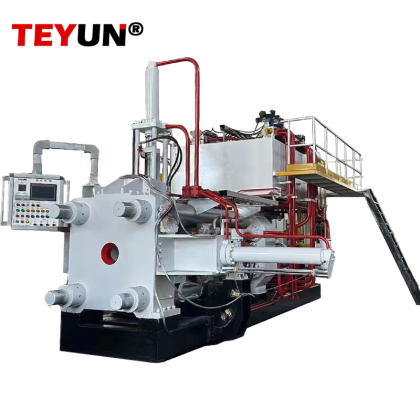

Vertical hydraulic metal baler application industry: Our vertical hydraulic metal baler is suitable for scrap metal, steel mills, non-ferrous metals, mining, metallurgy and other industries. In the scrap metal industry, our balers can pack scattered, non-ferrous metals, mining scrap iron, scrap steel, scrap copper, etc., which not only saves space, but also increases baling speed and reduces transportation costs. In steel mills, metallurgy and other industries, our balers have also been widely used, improving production efficiency and reducing production costs. Processable materials: Our vertical hydraulic metal baler can process a variety of materials, including scrap metal, steel, copper, aluminum, etc. In the scrap metal industry, our metal baler can pack such as scrap iron, scrap steel, scrap copper, etc. In steel mills, non-ferrous metals, mining, metallurgy and other industries, our balers can also adapt to different metal materials, such as steel, copper, aluminum, etc. Key point: Our vertical hydraulic metal baler has many advantages and is an ideal choice for your baling equipment. 1. Our balers adopt advanced hydraulic control systems, with features such as automation, high efficiency, low noise and other safety protection functions, which can improve production efficiency and reduce production costs. 2. Our balers also have good safety performance and reliable protection functions. 3. In addition, our vertical hydraulic metal balers also have functions such as automatic alarm and automatic shutdown, providing more convenience for customers. 4. Compact structure, small size, easy operation and other features, providing more convenience for customers. 5. Our balers can also be customized according to customer needs to meet the different needs of customers. Thank you for your attention and support. If you have any questions or needs, please feel free to contact us.

Read More

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported