Application and Effects of Gantry Shears

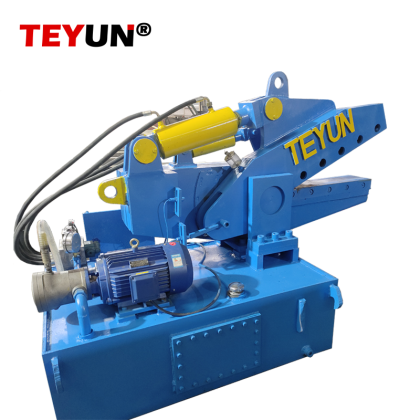

Hydraulic gantry shear can control the size of the shear opening arbitrarily according to the size of the material to be sheared, in order to achieve high working efficiency. Wide range of application, low energy consumption, widely used in scrap metal recycling and processing industry, small and medium-sized steel mills metal shearing, for the furnace smelting back to provide furnace material. Applicable materials of gantry shear: metal, iron, cast iron, thin iron, thin iron, light material, steel, colour steel tile, scrap steel, scrap iron, aluminium alloy, channel steel, angle steel, angle iron, copper plate, metal plate, aluminium profiles, scrap steel, aluminium plate, iron plate, steel plate, round steel, scrap metal. The effect of the use of gantry shear machine is mainly several aspects: 1. Speed. That is, the gantry shear machine output. 2. Self-weight. The self-weight of the machinery reacts to whether the material used is sufficient, and partly reacts to whether the gantry shear is durable. 3. Gantry shear power consumption. 4. Service life. You can ask the manufacturer or the person who bought the product customers. 5. Sealing performance. The sealing performance of the gantry shear directly affects the use and life. 6. The degree of integration. The high degree of integration of the model eliminates the time consumption of installation and commissioning, and also facilitates transport. 7. Materials. For example: gantry shear machine body cast steel parts are more durable than cast iron parts.

Read More

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported