The Development Trend of Hydraulic Gantry Shear

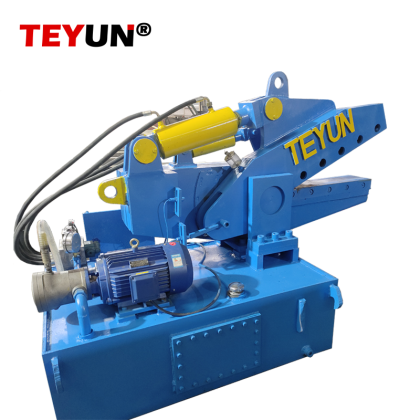

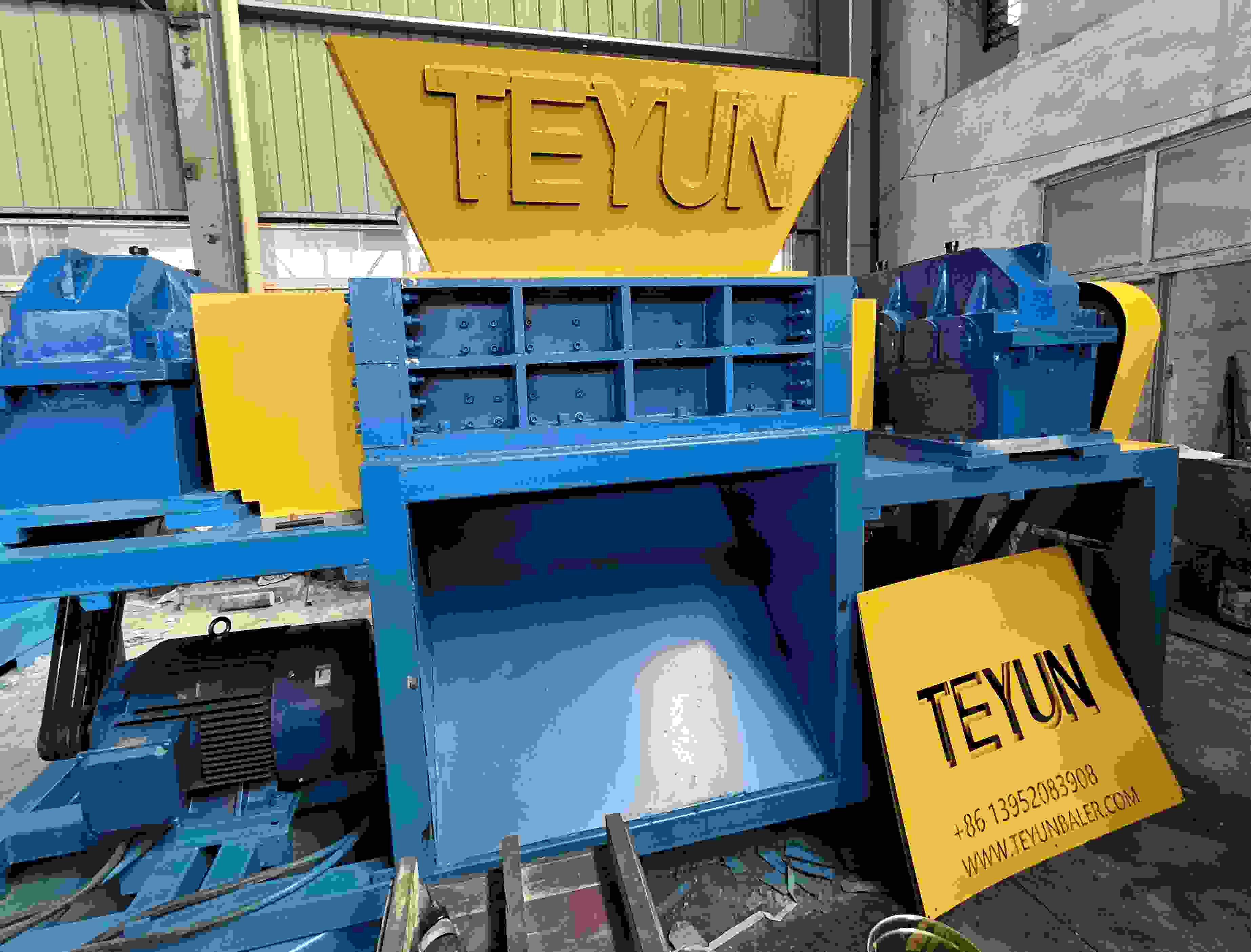

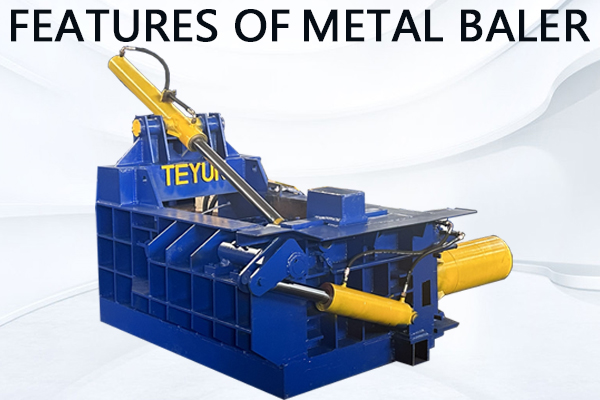

Hydraulic gantry shear equipment does not require a cement foundation fixed, mobile and good, at any time to change the workplace flexible business. No need to manually add lubricating oil, reduce maintenance time, save time, save labor. They are represented by scrap steel crushing line of large-scale equipment belongs to the typical import substitution products, the gross profit margin is quite considerable. In addition, large hydraulic gantry shears are widely used in scrap car processing. In the future, it is also possible to extend the gantry scrap steel shears and crushing lines to both ends to form a full range of products to meet the needs of different customers, and to make new breakthroughs in the dismantling equipment for scrap cars. In addition, it will also strengthen the technological upgrading and capacity expansion of metal renewable resources processing equipment, and accelerate the technological innovation and new product development in the field of non-metal renewable resources processing equipment and other areas. This equipment adopts hydraulic transmission, compared with the mechanical transmission type shearer, it has the advantages of small volume, light weight, low inertia, low noise, smooth movement, easy operation, flexible, large shear cutting surface, easy adjustment of scissors mouth, and so on. Working principle Gantry shearing machine has strong shearing force, low noise, fast shearing speed, strong and durable shearing tool, high hardness and long service life. It is suitable for various metal recycling companies, scrap car dismantling yards, smelting and casting industries. It can cold shear various shapes of metal for recycling and smelting. Various channel steels, I-beams, rails, scrap cars, bicycles, and ship plates can be sheared. This equipment is mainly used in the waste material recycling and processing industry, and small and medium-sized steel mills cold shear various metal section shapes such as round steel, square steel, channel steel, angle steel, I-beam, steel plate, steel pipe and other scrap metals. Gantry shears hopper automatically pushes materials and automatically shears. It has high production efficiency, is easy to operate, has high shearing efficiency, and can shear a wide range of materials. The operator controls the entire machine through remote control. It can shear about 70-90 tons of scrap metal materials every day. It is a powerful crushing device for scrap iron recycling.

Read More

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported