Introduction of gantry shearing machines

August 09, 2024

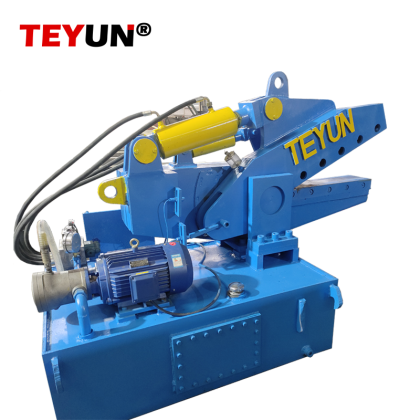

Working principle of gantry shearing machine

The operator loads the material to be cut onto the feeding box of the gantry shear and then positions the cutting head at the starting point of the cut.

When the cutting process begins, the cutting head moves along the rails of the gantry frame while the blade or cutting tool descends vertically, shearing the material along a predetermined path.

Operators can control speed and cutting force to ensure precise.

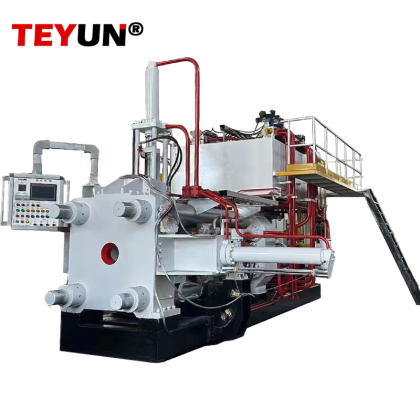

Application of gantry shearing machine

Gantry shears are typically used in industries that require cutting large material into small pieces with high precision. This includes metal fabrication, construction, automotive manufacturing and the other industry.

Gantry shears are versatile machines that can cut a variety of materials, including steel, aluminum, stainless steel, plastic and composites.

Advantages of gantry shearing machine

1. High precision: Gantry shears have excellent cutting precision, allowing for clean and accurate cuts, which is crucial in many industries.

2. Efficiency: These machines can significantly increase productivity by reducing labor and time required to cut large sheets of material.

3. Versatility: Gantry shearing machines can handle various materials and thicknesses to adapt to different production needs.

4. Reduce material waste: Precise cutting reduces material waste, thereby saving costs.

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported