Benefits of hydraulic briquetting machine

July 31, 2024

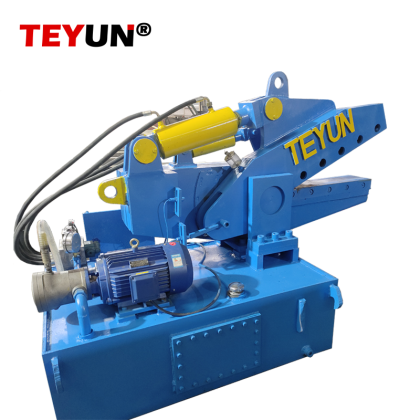

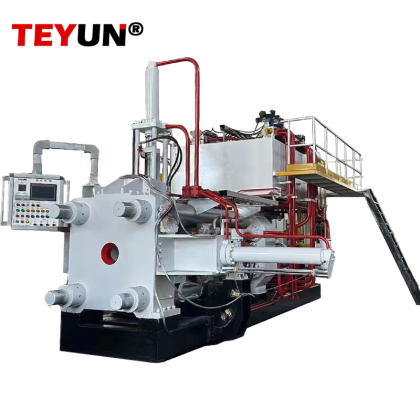

Briquetting machines are essential equipment for converting metal powder into compressed fuel briquettes. Hydraulic briquetting machines use hydraulic cylinders to compress the material. Raw materials are fed into the machine through a hopper, and hydraulic pistons apply high pressure to compress the material. This pressure forces the particles together and forms a solid compact. After the briquettes are formed, they are pushed out of the machine through specially designed molds.

Hydraulic briquette machines offer several advantages over other types of briquette production machines.

1. High pressure capability: Hydraulic briquetting machine can apply high pressure during the briquetting process, thereby producing dense and solid briquettes. This makes it suitable for applications requiring high density and strength of briquettes.

2. Consistent and uniform briquette production: The hydraulic system ensures consistent pressure throughout the production process. This results in the production of briquettes of uniform density and size, which is important for applications requiring sustained combustion and heat generation.

3. Lower energy consumption: Compared with other types of machines, hydraulic briquette machines are designed to consume less energy. Hydraulic systems operate efficiently, reducing energy waste and lowering production costs in the long run.

4. Easy operation and automation: Hydraulic briquette machines are usually simple to operate and do not require manual intervention. The process of feeding raw materials and removing finished briquettes can be automated, thereby increasing production efficiency and reducing labor requirements. In short, the hydraulic briquette machine has the advantages of high-pressure capability, stable briquette production, low energy consumption and easy operation. These advantages make it a popular choice for biomass pellet production. However, factors such as cost and specific production requirements must be considered when selecting the most appropriate type of dough maker for a specific application.

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported