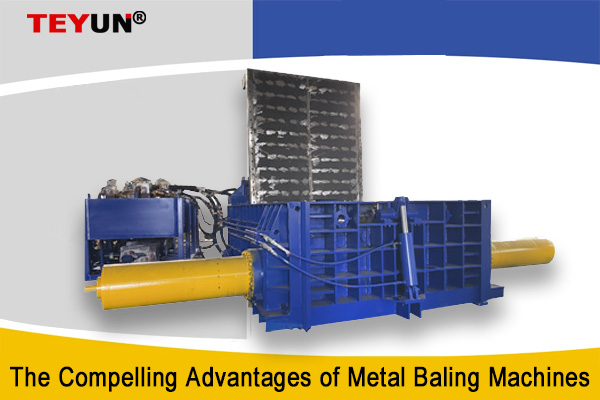

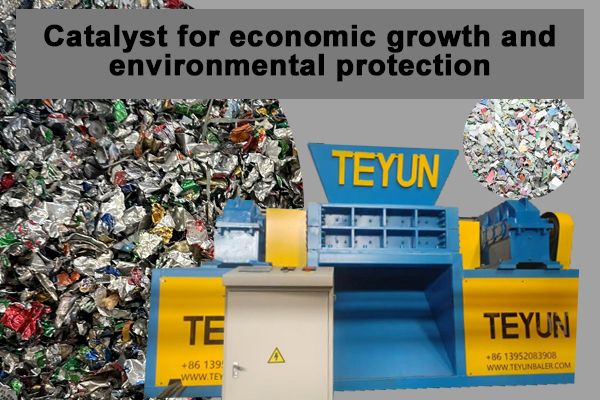

In the demanding world of scrap metal recycling and industrial operations, efficiency, safety, and cost control are paramount. Metal baling machines emerge as indispensable tools, transforming loose, cumbersome scrap into dense, manageable packages. Their advantages significantly enhance operational workflows and profitability: 1. Massive Volume Reduction & Space Savings: This is the most immediate and impactful benefit. Baling machines exert immense hydraulic pressure (often hundreds or thousands of tons) to crush and compress bulky scrap metal – think shredded cars, sheet metal offcuts, wire, cans, or turnings – into compact, rectangular bales. This drastically reduces the volume, sometimes by ratios of 10:1 or more. The result is vastly reduced storage footprint requirements, freeing up valuable factory or yard space for other activities and minimizing the sprawling, hazardous piles of loose scrap. 2. Optimized Transportation & Logistics: Dense, uniform bales are exponentially easier and more cost-effective to handle, stack, and transport compared to loose scrap. They maximize payload capacity on trucks, railcars, and shipping containers, significantly reducing the number of trips required. This translates directly into substantial savings on freight costs, fuel consumption, and associated emissions. Bales are also stable and secure during transit, minimizing spillage and safety hazards. 3. Enhanced Material Handling Efficiency: Bales are designed for mechanized handling. Forklifts and cranes can effortlessly move, stack, and load these uniform blocks. This eliminates the labor-intensive, slow, and often dangerous process of manually moving or shoveling loose, sharp, and heavy scrap metal. Loading and unloading times at processing facilities or mills are dramatically reduced, streamlining the entire supply chain. 4. Improved Workplace Safety: Loose scrap metal presents significant hazards: sharp edges, protruding wires, instability causing collapses, and heavy lifting injuries. Baling mitigates these risks. The compact bales have fewer exposed sharp points, are stable when stacked, and can be handled mechanically, keeping workers at a safer distance from the material itself. This creates a significantly safer working environment. 5. Increased Material Value & Marketability: Mills and foundries prefer dense, consistent bales. They are easier to feed into furnaces, melt more efficiently due to reduced surface oxidation, and often yield higher purity melt results. This consistency and ease of processing make baled scrap a more desirable commodity, potentially commanding better prices in the market compared to loose, mixed, or contaminated loads. 6. Reduced Labor Costs: Automating the compaction process significantly reduces the manual labor required for gathering, moving, and loading scrap. While the machine requires operation, it replaces numero...

We are online 7*24 hours to answer all your questions

-

Email : info@njteyun.com

Skype : sicily@njteyun.com

-

Tel : +86 13952083908

Whatsapp : +86 13952083908

-

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported