Why choose a horizontal baler?

When a company has an excess of recoverable material like cardboard, paper, or shrink wrap, managing these materials effectively – and ideally profiting from them – becomes essential.

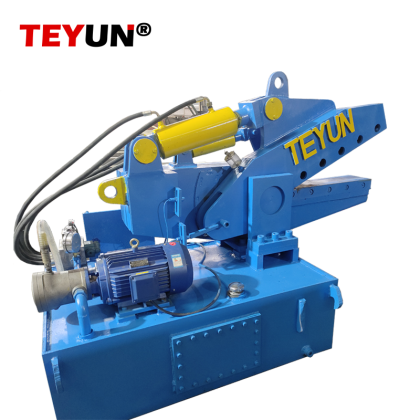

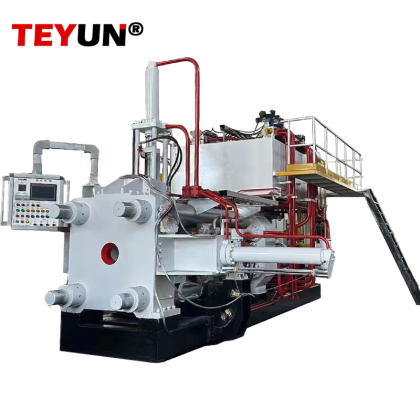

Options include disposing of them in a trash dumpster or compacting them in a baler or compactor. Of these choices, compacting is the only one that generates profit instead of costs. When the volume of recoverable material exceeds the capacity of a vertical baler, a horizontal baler may be the ideal solution. For volumes over 2 tons per day, a small horizontal baler is suitable. They are also beneficial when labor is limited or when processing requires the use of a tipper, conveyor, or other mass-loading methods.

Horizontal balers are larger, more expensive, and require more skill to operate than vertical balers but can be less labor-intensive.

How to choose a horizontal baler?

Which horizontal Baler is Right for You?

We offer an array of cutting-edge horizontal balers, meticulously designed to integrate with your business operations, ensuring optimal productivity in waste handling.

We need to ensure the model of baler according to your needs:

What material are you processing?

How much material are you processing (How many tons per month or per day).

Are you looking to process multiple materials?

How much space do you have?

How much labor do you want to dedicate to the process?

Do you have the necessary power to operate a bigger machine?

What is your budget? And what are your plans for growth?

When considering a baler purchase, it’s essential to start with clear long-term goals. Determine what you aim to achieve in the next 24–36 months and extend your vision to a 5-year projection. Balers are durable machines that can be updated as your business evolves.

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported