In recent years, scrap tire production has maintained steady growth, driven by increasing automobile sales. Waste tires are reusable resources, and regeneration and recycling are currently the mainstream processing methods. Waste tires can be reused into rubber particles, rubber powder, rubber asphalt, rubber artificial turf and other materials through crushing, grinding and processing. Widely used in construction, transportation, gardening and other fields.More and more customers are buying our tire shredders. The tire recycling business has good prospects and the market is huge.

There are three main uses for recycling waste tires.

1. Direct crushing: made into rubber powder and used to pave roads, which can save a lot of asphalt.

2. Reclaimed rubber produced through desulfurization: used to produce hoses, rubber pads, etc., and can also be added to new tires at a certain proportion, which can save a lot of natural rubber and synthetic rubber.

3. Through pyrolysis: decompose heavy oil, carbon black and other important chemical raw materials.

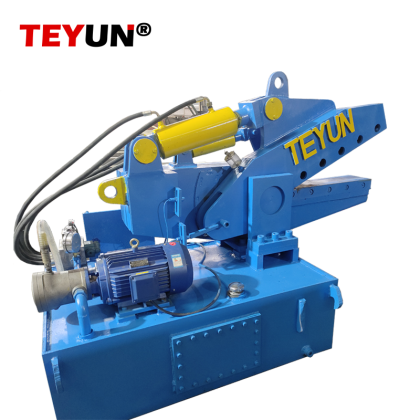

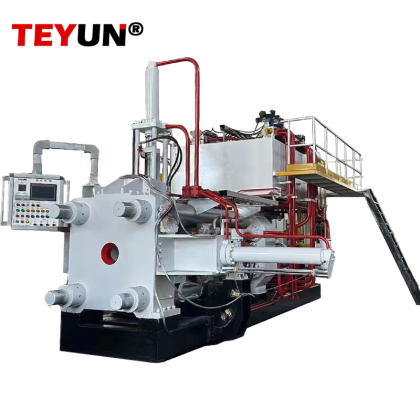

If you want to shred tires, you usually need a wire puller, a shredder, a magnetic separator, a rectangular screen, and some conveyors to connect these machines.

If you need to make rubber powder, you need to add a grinder. If you want very small particles, we recommend using three machines: coarse crusher, medium crusher, and fine crusher.

If you are interested in the shredder machine, you can contact us for the professional offer: info@njteyun.com.

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported