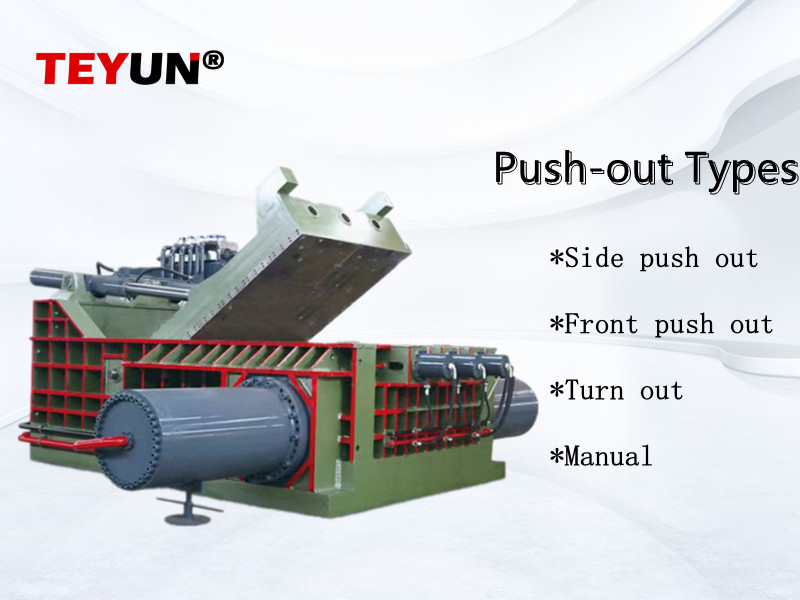

How to miantain the metal chips briquette press machine if it breaks down? Metal briquette press machines are used to compress and recycle: steel chips, iron chips, copper chips, aluminum chips or other metal powder and shavings. The final product after compression is like a cylinder with same size but high density. This process helps to make the metal chips and powder recycling much easier, reducing the waste, reduce the transports cost and stock space. Teyun has designed and produced the briquette press machines with many models 125ton, 315ton, 500ton, 630ton, 800ton or 1000ton ect. for over 21 years and has became one of the famous manufacturers in China. When using the briquette press machine, it may meet some problems, here are some tips from Teyun for your reference: 1. The feeding conveyor length control potentiometer of the metal briquetting machine is at the zero position. If adjusted clockwise, the strip length will become longer, otherwise it will become shorter; if the tape is in the zero position, the tape will not be output. 2. The metal briquetting machine is threaded incorrectly. Open the right door and thread the wire correctly according to the "Threading Process Method" or the threading diagram marked in the manual. 3. There is some matter in the extension part under the machine. The briquette press machine has been used for a long time and has not been cleaned and maintained in time, resulting in the accumulation of stolen goods in the machine. Therefore, more cleaning and maintenance should be done. 4. The gap between the belt feeding rollers of the metal chips briquette press machine is incorrect. See instructions for gap adjustment. Carefully adjust until the gap between the belt feed rollers is only 0.05~1mm larger than the belt thickness. 5. The PP tape is too thin or the metal briquette is too thick. Please carefully adjust the gap between the feed roller and the return roller according to the method in the manual. For the above five faults of the metal briquetting machine, the solutions are as follows: 1. Check the hydraulic oil in the machine. 2. Check whether the pressure regulating valve of the machine is loose. 3. Check whether there is any problem with the oil pump in the machine. To sum up, the rational use of metal chips briquetting machines can extend the service life of the machine, thereby saving costs and increasing revenue. The quality of equipment management has a decisive impact on the quantity, quality, cost and other economic and technical indicators of the company's products. Therefore, it is very important to maintain your briquette press machine. Of course, if you can not fix your problems please contact us we have the professional engineers to help you to solve them.

We are online 7*24 hours to answer all your questions

-

Email : info@njteyun.com

Skype : sicily@njteyun.com

-

Tel : +86 13952083908

Whatsapp : +86 13952083908

-

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported