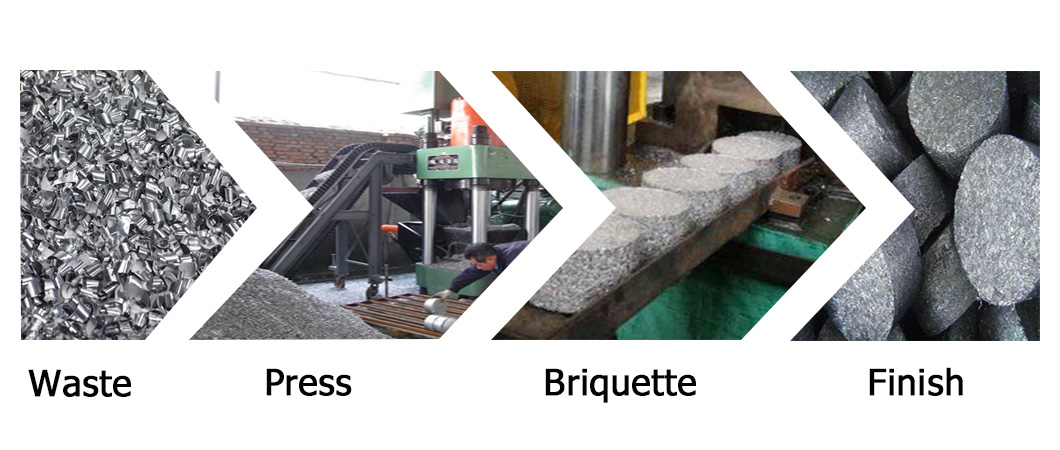

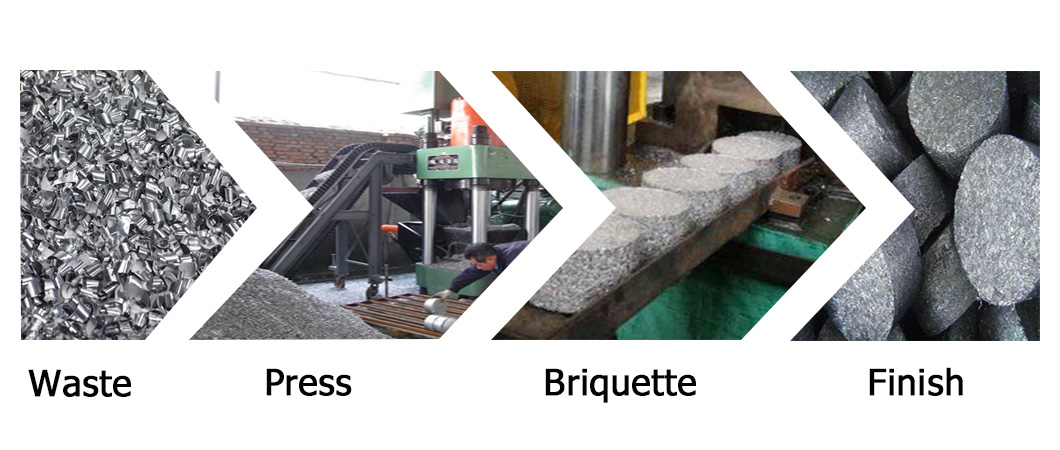

Introduction of Briquetting Machine

The briquetting machine can bale aluminum chips, steel chips, cast iron chips, and copper chips into blocks and return them to the furnace, which can reduce burning loss, save energy, and reduce carbon. It is suitable for aluminum alloy profile factories, steel casting factories, aluminum casting factories, copper casting factories and mechanical processing plants, etc.

Working Principle

The hydraulic system drives the hydraulic cylinder, and the hydraulic cylinder outputs high pressure to cold-press metal materials such as metal shavings and powder into cylindrical cakes, which is convenient for storage, transportation, furnace production, and reduces losses during recycling and reuse.

Recycling Functions

1. After being processed by the metal chip press machine, the waste metal chips can be compressed into metal chip round blocks by cold pressing and high-pressure compression. The whole process does not require heating, additives and other processes, which can prevent the remaining processes from affecting the characteristics of metal chips. These metal shavings compressed into round blocks can be directly used for incineration and remanufactured metal products.

2. The metal shavings in these metal discs will ensure the stability of the composition when they are returned to the furnace for incineration, and can also increase the density of the feed and reduce the number of feeds. The entire compression process of the briquetting machine reduces air pollution and energy consumption due to the reduction in feeding frequency, increases the furnace rate, and increases the profit margin of metal recovery and refining.

3. Compared with the block pressing machine on the market, the scrap metal briquetting machine is different in that we use a horizontal sealed design. The entire compression process is fully sealed, and there will be no waste liquid splashing around during the compression process, which ensures a clean environment and facilitates the collection of cutting fluid.

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported