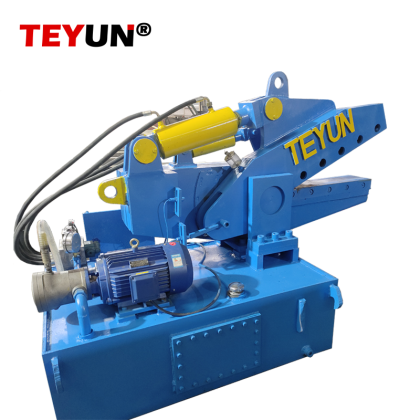

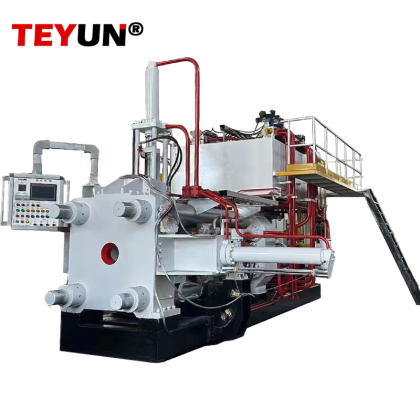

1, In the structure, the shredder is contained in the reducer, but the crusher is not contained in the reducer;

2, The shredder contains a built-in pusher box, while the crusher does not have a pusher box;

3, Shredder and crusher blades are different, shredder blade is diamond-shaped, while the crusher blade is sharp flat knife;

4, Shredder and crusher working principle is not the same, shredder is to rely on the knife roller low-speed torque to shear the material, while the crusher relies on the knife roller high-speed operation to cut the material.

5, Shredder and crusher for the size of the material there is a difference, shredder is to tear the material into irregular 20mm-200mm or even larger size block. The crusher is the block material is further broken into small pieces below 20mm, so as to achieve further processing conditions, such as cleaning and granulation.

6, The principle is different, the speed of the shredder is very slow compared to the crusher. The principle of shredder to tear the material is mainly by low speed, large torque, the speed difference between the shaft to tear, cut, tear the various materials. The crusher is a high inertia impact with and sharp edges of the rotating dynamic knife and rotating shaft on both sides of the fixed fixed knife, shear each other's way to cut the material.

7, Most of the material shredding processing for high strength, large size, load strong stubborn materials, crusher processing materials are mostly low load, small size of conventional materials. From the point of view of use, shredding has more safety, less manual operation, low noise and other advantages. Crushing, on the other hand, has a relatively high noise level and requires more manual operation and maintenance.

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported