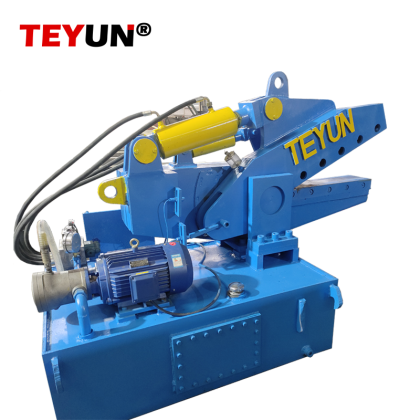

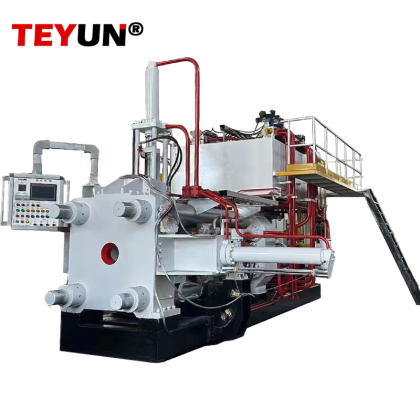

Selecting the optimal briquetting machine is pivotal in ensuring efficiency, achieving cost savings, and maintaining long-term reliability. This concise guide aims to assist you in making the most informed decision and providing adequate maintenance for your equipment.

Choosing the Right Briquetting Machine

1. Material Type: Clarify first the size, density, and compatibility of the scrap material you need to process.

2. Briquette Diameter: The briquettes diameter influences transportation costs, downstream processing, equipment selection, production efficiency, and provides precise solutions.

3. Production Capacity: Match the machine’s output (kg/hour) with your daily waste volume.

4. Budget: Balance initial cost with energy efficiency, durability, and maintenance expenses.

Operation & Maintenance Tips

1.Daily Use:Ensure uniform feeding to avoid jams; monitor hydraulic pressure and temperature.

2.Troubleshooting:Common issues include low briquette density (adjust pressure) or blockages (clean dies regularly).

3.Maintenance:Lubricate moving parts, inspect seals, and replace worn-out components promptly.

Safety Precautions

1. Wear protective gear (gloves, goggles) when operating the machine.

2. Never bypass safety interlocks or overload the system.

3. Train operators on emergency shutdown procedures.

Optimizing productivity and extending the lifespan of your equipment is easily achievable by selecting the appropriate machine and adhering to proper maintenance procedures. For tailored advice on the most suitable briquetting solution to meet your specific requirements, feel free to reach out to us.

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported