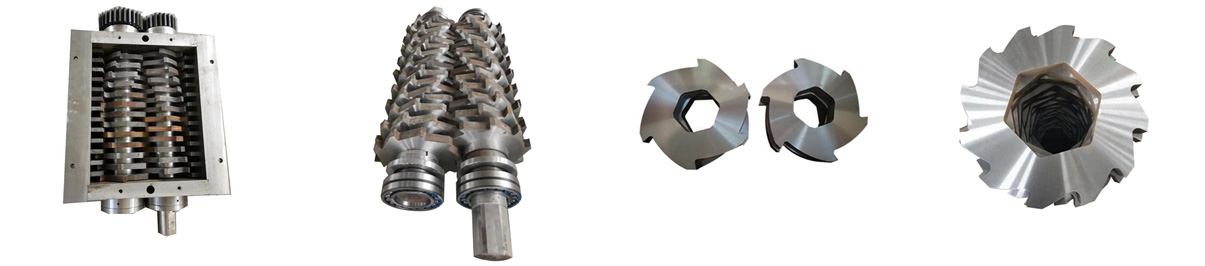

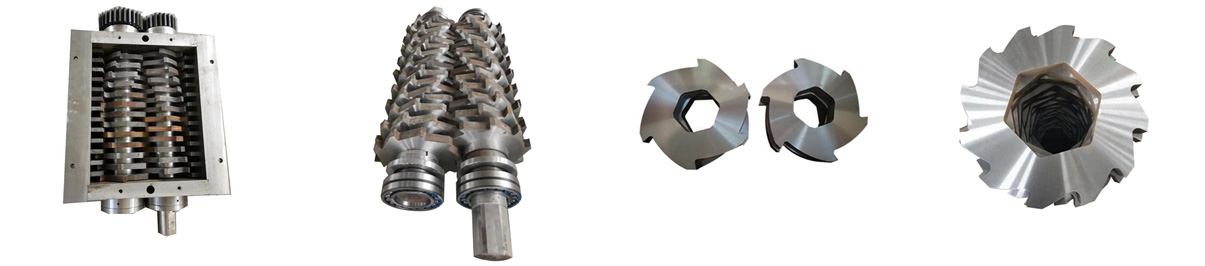

The main models of shredders include single-shaft shredders, double-shaft shredders and four-shaft shredders. So how to choose a blade for each type of shredder?

The single-shaft shredder blades mainly crush soft materials such as plastics. We must choose materials with high quenching hardness, wear resistance and impact resistance. Now most of them choose Cr12MoV, D2, DC53. The general hardness can reach about HRC60°, and some Customers with high requirements may even use more expensive LD (7Cr7Mo2V2Si), W6Mo5Cr4V2, and other materials. The hardness reaches above HRC62°. It contains high alloy elements such as W and Ni, which are more wear-resistant and impact-resistant, making the shredder blade more suitable for use. The service life is longer, the frequency of tool changes is reduced, and the cost performance is higher.

Double shaft shredder blades and four shaft shredder blades are mainly made of 55SiCr, H13 and other materials, but this is only for some ordinary objects and general service life, similar to plastic bottles, wood, domestic garbage, cans, ordinary Metal, etc., for some customers who have high requirements for shredding high strength and long service life, we need to choose appropriate materials for shredding different objects. The double-shaft shredder shreds some relatively soft materials such as aluminum and copper. For metal materials, or some plastic and rubber materials, which require a long service life, we must choose materials similar to D2, LD, etc., because aluminum, plastic, rubber and other materials are sticky and will need to be shredded by a dual-shaft shredder for a period of time. Shredding and squeezing, these materials will inevitably heat up and stick together with the blades. Therefore, if you want to have a long service life and uniform shredded particles, you must choose these materials with strong quenching properties and high wear resistance; for shredder blades to shred some High-strength steel is similar to automobile plates. Metal materials with a yield strength of more than 550Mpa or even more than 1000Mpa, such as beam steel, must be made of impact-resistant and tough materials such as H13Ni and HMB to prevent the blade from chipping or blunting.

Teyun always use good blades, to longer blade life and achieve customers requirements.

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

Address : Mingjue Industry Park, Lishui District, Nanjing City, Jiangsu Province

français

français русский

русский español

español العربية

العربية 日本語

日本語 Tiếng Việt

Tiếng Việt 中文

中文

IPv6 network supported

IPv6 network supported